Sound Control Pty Ltd has vast experience in controlling noise pollution from gas turbines that is a priority for many Government and Environmental bodies. Our designs provide optimised attenuation for both inlet and exhaust applications that ensures the facility meets the relevant design criteria. The operational conditions of gas turbines require advanced engineering expertise from material selection, thermodynamics, fluid mechanics and manufacturing/welding of which Sound Control is eminently qualified.

Design Features Include:

- Standard or bespoke design to suit various applications and arrangements.

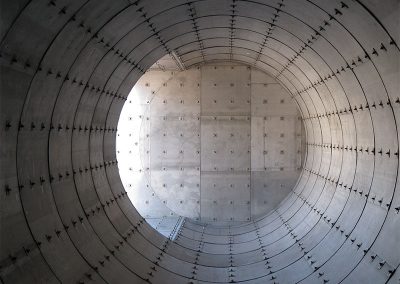

- Circular or rectangular in design.

- Unique non-welded fixing methods for internal silencer element to accommodate rapid thermal expansion experienced on GT start-up.

- Specialty bagged absorptive materials ‘pillows’.

- Noise reduction capabilities from 10 dB(A) to 50dB(A).

- Minimal pressure loss to allow maximum GT efficiency.

- Manufacture in a variety of materials including Coated Steel, Stainless Steel and speciality alloys, capable of handling temperature.

Optional Extras:

- Acoustically and thermally rated expansion joints manufactured to suit attenuator cases (optional extra).

- Exhaust Stack:

- Designed to accommodate environmental loads.

- Fabrication – AS4100, AS1554.

Completed Projects:

- Yurralyi Maya Power Station 5 x 45MW LM6000, WA:

- Exhaust Stacks, Exhaust Silencers, Inlet Silencers & Flexible Joints.

- Parraburdoo Power Station 1 x 45MW LM6000, WA:

- Exhaust Stacks, Exhaust Silencers, Inlet Silencers & Flexible Joints.

- Senior Thermal? LM2500, WA:

- Exhaust Silencers.

- Roma Power Station 2 x 40MW Frame 6, QLD:

- Exhaust Silencers, Exhaust Plenums, Exhaust Stacks.